SFC’s R&D team works in close cooperation with our customers in order to ensure the designed product is feasible for manufacturing and to optimise its quality, price and performance.

Our strengths are:

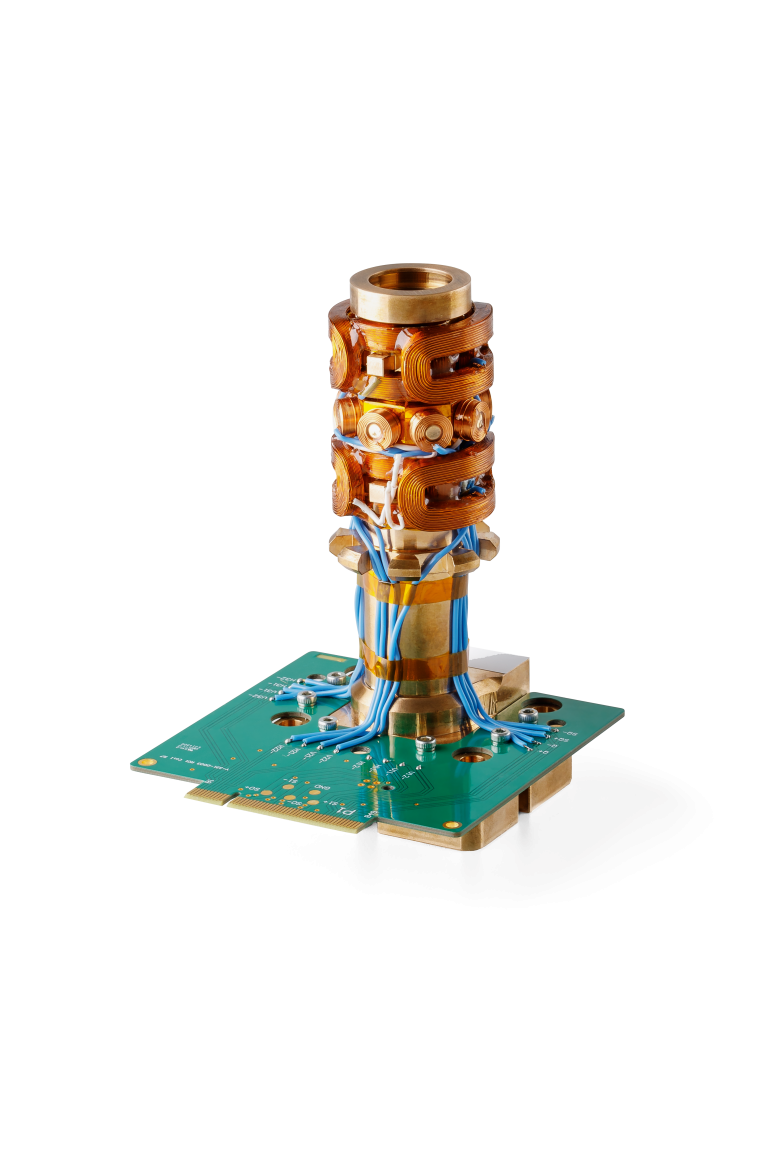

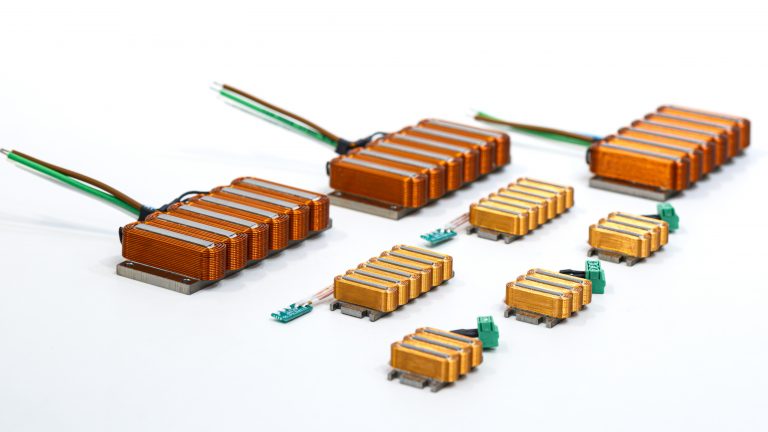

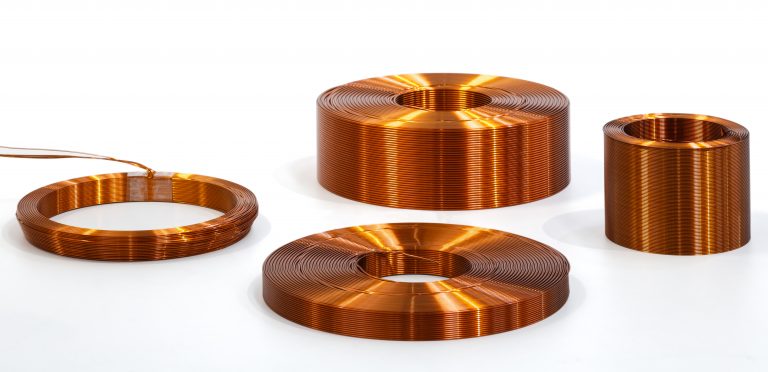

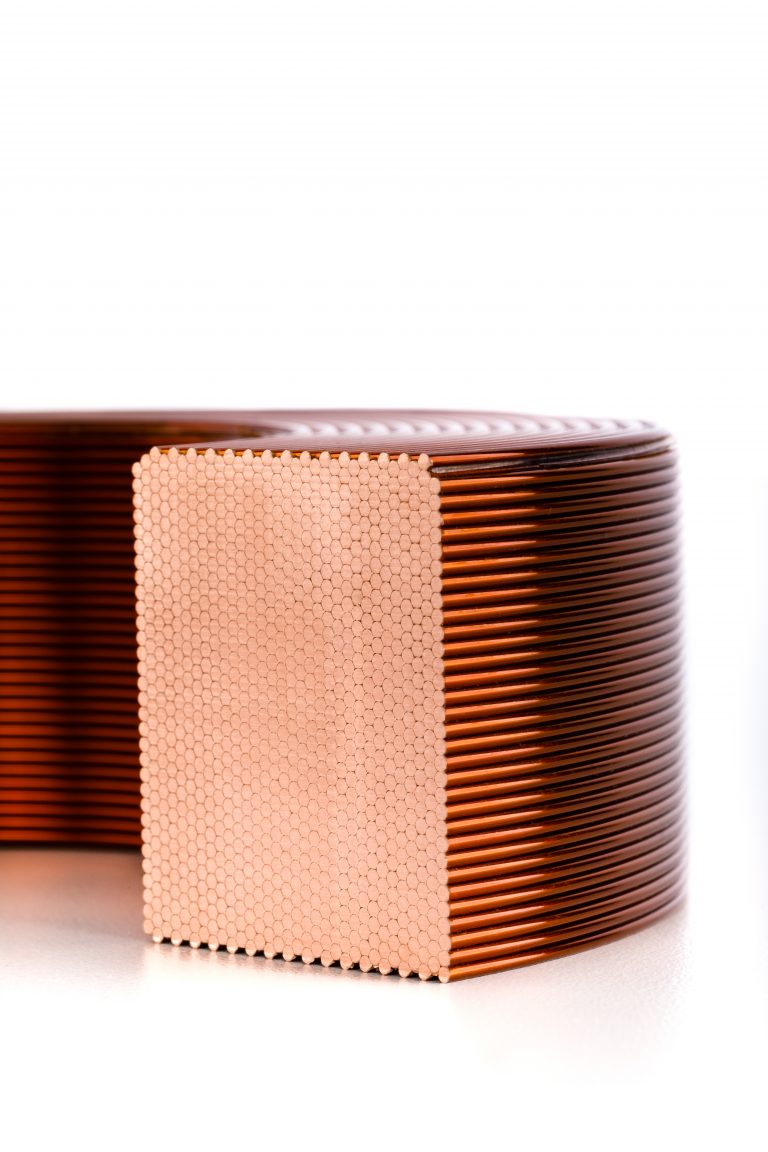

SFC has a lot of experience and knowledge in winding and bending coils. We have the following capabilities:

For our customers who develop coils & linear drives for special operating conditions, potting is used to improve the thermal performance:

Several automatic or manual tests and inspections are carried out. To secure the quality of our products, 100% of our coils & linear drives are tested with high-voltage, inductance, resistance, magnetic field direction, water pressure and flow testing. Complex mechanical parts are tested in an early stage on our automated 3D measuring machine.

For serial production SFC has its own production facility in Cluj-Napoca, Romania. With highly skilled and trained people, the Cluj factory delivers coils & linear drive products in quantities from 10 to 10,000 units a year.

SFC Cluj strives to be one of the most flexible coils suppliers in the industry with an ability to manage rapid design changes, schedule adjustments and use inventory management programs to achieve best-in-class cost and capacity management.

SFC has dedicated in-house teams to manage all aspects of service, engineering and manufacturing requests for a fast and accurate response to customer requests.

Custom product request

Send us a mail with your technical requirements.